Jute Geotextile (JGT) and agrotextile (JAT) made from fibres of jute plant have proved effective in addressing soil-related problems in civil engineering and agriculture. Years of research coupled with concurrent field applications have made it possible to develop appropriate fabrics for JGT and JAT utilizing its distinctive features. In India use of JGT and JAT is gradually gaining ground. JGT has been highly successful in controlling riverbank erosion and stabilizing roads. JGT is also the most sought-after fabric for surficial soil erosion control. JAT has been effective in weed suppression, afforestation in arid zones, soil conservation and as a facilitator of plant/sapling growth. Depleting petroleum reserves and deteriorating environment should make these two natural textile fabrics attractive to the end users not only from economic and technical considerations, but also as a natural intervention to rein in engulfing environmental pollution. This article highlights features that make JGT and JAT distinctive.

Introduction

Jute, a natural, eco-friendly biodegradable and annually renewable bast fibre grows abundantly in India and Bangladesh in particular. As reported by Shivani Sridhar, in India, the annual production of jute is of the order of 1.6 million tons with jute sacks being the potent product. Jute industry in India is one of the oldest agro-industries in the world. In India alone about 0.7 million people are dependent on jute production, its manufacture, and marketing for their livelihood (Sridhar 2015:60).

The ingress of man-made polymers poses a threat to the jute industry which is why the diversification of jute products has become an imperative necessity (Sridhar 2015:60). Indian Jute Industries’ Research Association (IJIRA) has developed a number of jute diversified products like Jute Geotextile (JGT) and Jute Agrotextile (JAT) through extensive R & D work utilizing the unique intrinsic properties of jute fibres like high initial tensile strength, low extensibility, high water absorbency, excellent drapability and spinnability (Sridhar 2015:60). Varieties of JGT and JAT namely, woven, non-woven, open mesh woven, pre-fabricated vertical jute drain (PVJD), jute sleeve etc. have been developed by IJIRA with the support of Jute Manufactures Development Council (JMDC). Laboratory study followed by successful field applications has established the efficacy of these products. It is relevant to mention that all geotextiles act as change agents to soil to improve its engineering performance, and its long-term durability is not a technical necessity. Bio-degradability is therefore both a technical and environmental advantage. Man-made geotextiles are questionable from an environmentalist's perspective despite their longer durability. The stress is now on adopting bio-engineering measures to address soil-related problems in civil engineering. The depletion of petroleum reserves and deteriorating environment in the planet should make JGT and JAT more attractive to the end-users. This article indicates the salient properties of JGT and JAT along with references to a few case studies substantiating the efficacy of these two products.

Jute Geotextile (JGT) and Jute Agrotextile (JAT)

Jute, known as a golden fibre for its gold-like texture, is a unique textile grade lingo-cellulosic fibre. Its main chemical constituents are alfa cellulose (62%), hemicelluloses (24%), lignin (12%) and others (2%). Its high tenacity (40gm/tex), low elongation at break (1.4%) and moisture content (13%) at 65% RH give it an edge over other geotextiles (Sridhar 2015:60). JGT is a permeable textile fabric available in woven or non-woven form, used in or on soil to improve its engineering performance. JAT is a woven, or non-woven/fabricated product used to achieve a higher agricultural yield by enhancing the agronomical characteristics of soil and suppressing growth of unwanted vegetation like weeds.

Types of JGT and JAT available along with their Specifications

JGT and JAT are tailor-made products. Site-specific products can be manufactured depending upon end-use requirements. Stronger (40kN/m) and wider (upto 5 m) fabric with finer porometry (100 micron) can easily be produced. However, specifications of some standard JGT & JAT are given as reference in Table 1 and Table 2 below.

Table 1: Specifications of widely used Jute Geotextile

|

PROPERTIES TYPE |

Weight

|

Thickness

|

Strength (MD x CD) |

Elongation (MD X CD)

|

Water holding capacity |

Pore size (O90)

|

|

|

(g/m2) |

(mm) |

(kN/m) |

(%) |

(%) |

Micron |

|

Woven |

760 |

2 |

20 x 20 |

10 x 10 |

400 |

200 |

|

Nonwoven |

500 |

4 |

4 x 5 |

20 x 25 |

600 |

400 |

|

Open mesh |

500 |

4 |

10 x 7.5 |

-- |

500 |

-- |

Table 2: Specifications of widely used Jute Agrotextile

|

PROPERTIES TYPE |

Thickness

|

Strength (MD x CD) |

Water holding capacity |

|

|

(mm) |

(kN/m) |

(%) |

|

Jute sleeve |

1 |

7.5 x 6.5 |

300 |

|

Open mesh |

3 |

12 x 12 |

400 |

Potential Applications of JGT

Case Studies with JGT in India

A number of field applications has been carried out with JGT. Significant findings from India are presented below.

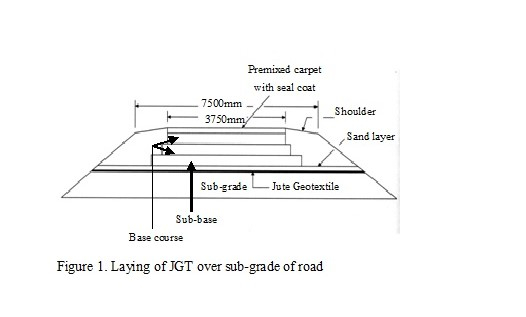

Road Construction

In all the field applications in roads, it has been observed that sub-grades, despite being expansive, experienced increase in CBR in the range of 1.5 to 3.0 times the control value. As soil consolidation is a time-dependant process, with the passage of time CBR shows a sustained rise even after a period of eight or nine years (Sridhar 2015:59). Void ratio and compression index of the sub-grade soil registered a downward trend while its dry density increased. In most of these road applications, woven JGT with a tensile strength of 20 kN/m to 25 kN/m were used. Busy and heavy roads may call for the use of woven JGT of higher tensile strength (30 kN/m and above) (Sridhar 2015:59). The schematic diagram of installation of JGT in road construction is shown below in Fig. 1.

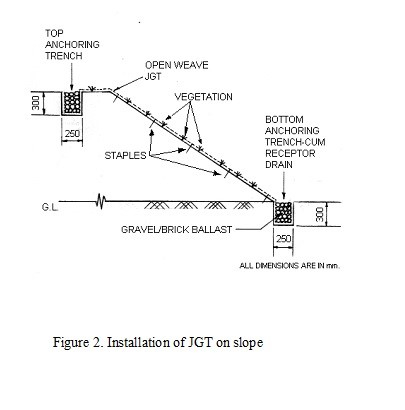

Slope Stabilization

Open-weave JGT was used to stabilize slopes on hills and embankments followed by the creation of vegetative cover that protects the slopes from destabilization on bio-degradation of JGT. In almost all case studies, the yield of vegetation improved by around five times the usual yield (Kg per ha.) after three years of plantation. Moisture conservation, reduction of the velocity of surface run-off and quality improvement of soil were in evidence in all the applications. The extent of improvement of soil character depends on selection of the vegetation, soil type and climatic features. The choice of open-weave JGT (500 gsm or above) depends on the amount and intensity of precipitation and slope inclination. The schematic diagram of installation of JGT in slope stabilization is shown below in Fig. 2.

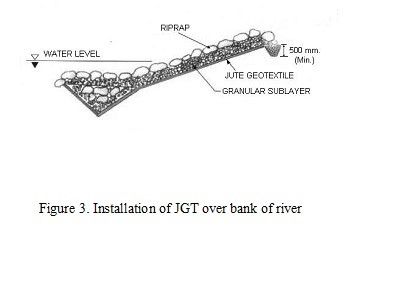

River Bank Protection

Woven JGT smeared with bitumen (90/15 grade) was used in all applications related to erosion control in river and waterways. This was done with a view to protecting JGT yarns from direct exposure to water. Moreover, time of bank soil consolidation in river depend on the nature of flow (two-way or one-way), existence of vortices at the toe of the bank slope and other hydraulic factors. In the tidal reach of a river (e.g., the Hugli in West Bengal, India), mangrove plantation was attempted to reinforce the strength of the bank soil through its roots. In non-tidal reaches (one-way flow), usual boulder rip rap was used. The schematic diagram of installation of JGT in river bank protection is shown below in Fig. 3.

Use of JGT in river bank protection proved to be an effective alternative to the conventional method of granular overlay on the eroded bank with respect to capital investment and recurring maintenance cost. Normally, one to two years is observed to be adequate to optimize bank soil consolidation in unidirectional rivers and two to three years for tidal rivers.

Potential Applications of JAT: Case Studies with JAT in India

In absence of vegetative cover, the top soil is eroded by overland run-off that usually flows as sheets. The rate of top soil erosion increases, understandably, with the steepness of ground and the intensity and duration of precipitation. It takes years to revamp a denuded ground through deposition of new soil. In fact, denuded areas become vulnerable to erosion if they are not overlaid by vegetation of the right type in time. Moreover, continued surficial soil erosion causes aggradation of beds of rivers, canals and drainage channels depleting their drainage capacity and enhances the probability of floods caused due to excessive rain fall. JAT aids in quick growth of vegetation and checks the loss of nutrients in soil. The mulching effect of JAT on its biodegradation aids 'greening' of the soil for a substantial period due to creation of a conducive micro-climate including the retention of optional humidity of the top soil and preservation of the existing nutrients. JAT adds nutrients to the soil at micro level.

Surficial Soil Erosion Control

A field trial was carried out on a tea estate in Assam to observe the effectiveness of JAT in controlling soil erosion and nutrient loss. Data obtained after two years of monitoring indicated that JAT was effective when used in combination with green crop, in reducing soil erosion by around 96% and controlling nutrient loss to the tune of 95%. Usually 500 gsm non-woven JAT is used.

Weed Suppression

Another application of JAT is in the field of weed suppression. The objective of weed suppression is to suppress growth of weeds on the one hand and to foster growth of the desired vegetation on the other. The efficacy of non-woven JAT is established through field trials conducted on two tea-gardens in the north-eastern region of India. The trial for weed suppression was in Assam. The fabric was laid between two rows of plants over the weeds and fixed to the ground by wooden staples. Weedicides were also used in conjunction to study the effects comparatively. Results confirmed that under the given climatic soil and topographical conditions non-woven JAT could reduce weed emergence by 65%. Addition of weedicides could enhance the extent of suppression by a further 13% maximum. Usually dense non-woven JAT (500 gsm/1000 gms) are used for this purpose

Afforestation in Semi-Arid Zone

A study was conducted to find the effectiveness of JAT in fostering plant growth in a semi-arid, laterite soil zone in West Bengal. Fabric was laid between the rows of plants and pegged to the ground. The height of plants was measured after three and six months. The growth of plants was found to be more pronounced with Jute Agrotextile and was almost double the growth under control conditions.

Growth of Sapling in Jute Sleeve

A study was conducted to observe the efficacy of jute sleeves in helping to raise saplings as compared to conventional poly-sleeves at nurseries in high altitudes in the lap of the Himalayas (Sikkim). The trial was conducted at different altitudes ranging from 1350 metres to 2600 metres above mean sea level. Jute sleeves (size 22.5 cm x 15 cm) with one end open and the other end closed were used to fill the soil bulb with the root. The growth rate was observed for one year. The grown-up plants were then transplanted directly into the soil. The removal of the jute sleeves was not necessary as jute was supposed to coalesce with the soil and ultimately became an integral part of it. The soil bulb contained compost manure of cowdung and sand. It was observed that with jute sleeve there was faster and better growth of sapling and better aeration. Extremes of temperature could be evened out. No ice formation was noticed within the sleeves. A high survival rate (90%), and the spread of roots through fine openings of the jute sleeves were observed. No extraction at the transplantation stage was necessary, unlike in the case of poly sleeves. Jute sleeves are found to be superior to poly-sleeves in performance, installation and after care. The cost of jute sleeves is, of course, higher.

Further Research and Development Work

IJIRA&JMDC are jointly continuing extensive research and development activities to develop newer varieties of such products with improved physical, mechanical and hydraulic properties like strong, durable and cost-effective fabrics for various applications including paving fabric. The case studies referred to are not exhaustive and there remain areas where there has not been experimentation. Efforts in this direction have taken off.

Inferences

In the case studies presented above, Jute Geotextile was found to have performed as expected, having executed the basic functions in three different applications in civil engineering. The case studies confirmed that Jute Geotextile principally acted as catalyst or change agent in improving the engineering performance of soil. Improvement was achieved basically as a result of ridding of the soil of the water usually entrapped in plastic soils, on the one hand, and retention of fines on the other (filtration function). JGT also acted as a drain within its own thickness. Its inherent capacity of water absorption helped in the lateral dispersion of water. The design of porometry assumes significance in this respect. Retention of fines and permittivity act under contrasting porometric parameters. Experience plays a big role in deciding the right porometry on the basis of established empirical relations. The installation stresses were absorbed by the high initial strength of JGT.

Durability of JGT beyond two season cycles, as earlier indicated, was found not a technical necessity, as soil on reaching the maximum dry density becomes self-reliant and independent of the functions of any Geotextile. In the case studies with Jute Agrotextile in which strength of the fabric is of less significance, its effectiveness as mulch, temperature-conditioner and humidity-regulator is established. Dense non-woven JAT acts as a barrier to air and sunlight and helps in suppressing the growth of weeds. JAT also supplied nutrients to soil though at the micro-level. In fine, both JGT and JAT can, to a large extent, reduce concerns about environmental pollution in their respective applications. Techno-economically the products have been found to be highly effective. The cost of the products are given at www.jmdcindia.com.

These two jute diversified products—more aptly, 'technical textiles'—fit in with the emerging global trend in adopting eco-friendly as well as bio-engineering measures, and deserve bigger support from discerning end-users.

(Talk presented at the 5th International Conference on Earth Reinforcement, Fukuoka, Japan, November 14-16, 2007)

Reference:

Barooah, A.K., H. Goswami and U. Dutta, 1997. Biodegradable Jute Geotextile for Integrated Soil and Crop Management in Tea Estates : Soil Conservation (part – I) . Workshop on Jute Geotextile.

Choudhury, P.K., P.K. Chatterjee, and U. Dutta. 1999. A Low Tech. Approach for Forests: 1st Asia–Pacific Conference on Water and Bioengineering for Erosion Control and Slope Stabilization.

Juyal, G.P., and K.S. Dadhwal. 1996. Geo-jute for Erosion Control with Special Reference to Mine-spoil Rehabilitation. Indian Journal of Soil Conservation 24.

Ramaswamy, S.D. and M.A. Aziz. 1989. Jute Geostextile for Roads. International Workshops on Geotextiles.

Rao, P.J. Bindumadhava and N. Venisiri. 1998. Construction of Highway Embankment on Soft Marine Soil using Jute Geotextile. 6th International Conference on Geo-synthetics.

Sanyal, T. 1992. Control of Bank Erosion Naturally: A Pilot Project in Nayachara Island in the River Hugli. National Workshop on Role of Geosynthetics in Water Resources Projects.

Sanyal, T. & P.K. Choudhury. 2003. Prevention of Railway Track Subsidence with Jute Geotextile: A Case study under Eastern Railway. Workshop on Applications of Geosynthetics in Infrastructure Projects.

Sridhar, Shivani. 2015 ‘Optimization of Jute Geotextiles in Pavement Design: State of the Art’, International Journal of Emerging Research in Management and Technology 4.8:59–67.