Throughout human history, coal was mined as a low-value fuel, used by smiths for smelting metal ore and in households for firing hearth. From the 1760s onwards, the potential of steam energy as a substitute for human and animal energy was discovered, and the value of coal soared. Anthracite (high-grade coal with a carbon content between 86% and 98%) was the new gold; its value reflected in its epithet ‘Black Diamond’. As a coal-powered Industrial Revolution kicked off in Britain, it gave rise to the development of power-driven machines, which permanently changed the nature of industries and manufacturing.

From Britain, the Industrial Revolution trickled to its colonies, including India. In India, exploration for coal deposits started in the late eighteenth century. In 1774, John Sumner and Suetonius Grant Heatly of the British East India Company found coal near Ethora, a rural suburb near Asansol, in West Bengal. Initially, coal mining happened in an unorganised manner, but by 1820, Raniganj Coalfield—India’s first coalfield—was established. In the 1830s, operations at Raniganj Coalfield was taken over by the first Indo-British joint venture Carr, Tagore & Co., set up by wealthy investor Prince Dwarkanath Tagore, grandfather of poet Rabindranath Tagore.

In 1843, rival Jeremiah Homfray’s mine was taken over by Carr, Tagore & Co. to form the Bengal Coal Company (BCC). They immediately closed Homfray’s mine and monopolised the trade. Bengal’s industrial development took off, powered by coal mined and supplied by BCC. After the formation of BCC, the coal industry started getting regularised, but Dwarakanath Tagore, the prime investor, had started losing interest, and he wanted to explore a new technological innovation that he had witnessed on a visit to England—the steam engine.

Steam locomotives were initially used in hauling coal from underground mines. Soon it was driving passengers. England had its first locomotive driven inter-city public railway in 1830 when the Liverpool and Manchester Railway started operations. Prince Dwarakanath Tagore recognised the potential of steam locomotives and wanted to bring the technology to India, to make transportation of coal from Raniganj to Calcutta much easier. However, in an era when Indian entrepreneurship was discouraged by European stakeholders, he was thwarted in this attempt by the East Indian Railway Company, and his plans did not materialise. Nine years after Dwarkanath Tagore’s death, in 1855, the first steam engine of the East Indian Railway Company chugged into Raniganj.

Between 1850–1900, Jharkhand underwent a coal-mining boom. Large-scale mining operations destroyed the ecosystem of the Chhota Nagpur region. Mine waste and toxic effluents were dumped in the Damodar River, one of the major water systems of eastern India, which due to large-scale coal mining operations, is now one of the most polluted rivers in India. Other than environmental damage, coal-mining operations have come at a huge cost for the native population, the Adivasi and Scheduled Caste/Scheduled Tribe, most of whom are economically disadvantaged, belonging to the Below Poverty Line (BPL) families. These displaced communities had earlier been engaged in agriculture, hunting and rearing livestock, but now either work in the mines or as migrant labour.

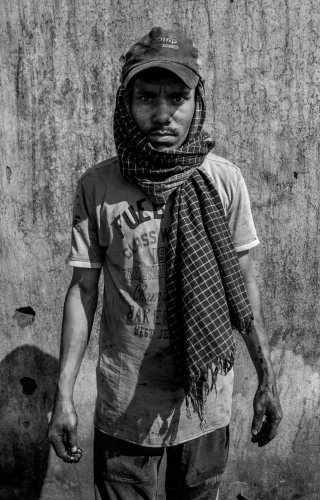

Cheap coal is abundant in Jharkhand. Much of it comes from the Piparwar operational area of Central Coalfields Limited, a subsidiary of Coal India Limited, an undertaking of the Government of India. Several mines operate in this area, located mainly in Chatra district, and some parts of Ranchi district. Amongst the biggest coalfields in India, North Karanpura Coalfield in Chatra district has reserves of 14 billion tonnes of coal, around 9 per cent of India's total coal reserves. Ashoka open-cast project in the North Karanpura Coalfield commenced operations in 1995. In 2013–14, it produced 7.50 million tonnes of coal. Every village in this region is directly or indirectly engaged with the coal industry. Every day, thousands of villagers in Piparwar go to work in the mines to support their families. For a meagre wage, men and women break coal and carry it in baskets on their head to load on trucks. Much of the coal mining is illegal and unregulated, controlled by the coal mafia.

Everywhere you look in Piparwar, there is a coal mine. A fine layer of coal dust covers everything. The main source of air pollutants, like coal dust, comes from the transportation of coal, but also from drilling, blasting and the loading and unloading of overburden (the upper layer of soil and rock removed in open-cast mining to get to the coal below). These pollutants cause significant damage to public health and safety. For example, suspended coal dust is a leading cause of coal worker's pneumoconiosis, or black lung disease, caused by inhaling coal dust.

Coal dust is a by-product of open-cast mines, most of which are in Piparwar. In open-cast mining, a massive pit is dug, and coal is removed from the bottom. The pit gets wider towards the top. The upper diameter can be as much as a kilometre wide. Compared to tunnelling, open-cast mining is considered more efficient but produces a significant amount of overburden. Open-pit mining causes long-term soil erosion, which ultimately contributes to change in surface hydrology, groundwater levels and flow paths, polluting rivers, ponds and other water resources. Not just water bodies, environmental degradation affects the topography of the land, agriculture, forests and biodiversity in the areas surrounding open-pit mines.

In Piparwar, what adds to the problem of coal dust and open-cast mines is effluent from coal washeries, coke-oven plants and soft-coke batteries. Each year they release hundreds of millions of tons of solid waste produced by coal-burning, including fly ash, bottom ash, and flue-gas desulphurisation sludge. Due to all these factors, coal is the largest contributor to the human-made increase of carbon dioxide in Earth's atmosphere. In 2008, the World Health Organization (WHO) and other organisations calculated that coal particulates pollution cause approximately one million deaths annually worldwide. The global spread of the Covid-19 pandemic added to the already existing complications of air pollution related illnesses, further increasing the risks to the respiratory system.

Currently, India is the third-largest (after China and the USA) emitter of carbon dioxide in the world (though low on emissions per capita). As signatories of the Paris Agreement, India will need to reduce its dependency on coal if it has to reverse this spiralling environmental collapse. As nations get together to mitigate climate change through the reduction of fossil-fuel emission, India will need to increasingly invest in alternative energy like nuclear power, wind power, solar power, tidal power, bioenergy, battery technology and natural gas. Problem is, even though clean energy investment is increasing, coal isn’t going away anytime soon. The coal sector is a major source of revenue for states and the central government. Also, coal still provides around 70 per cent of the country’s electricity. Till coal becomes commercially unsustainable and loses government patronage, Piparwar will continue to be hell on earth.

This photo-essay has been created as part of the Sahapedia Frames Photography Grant, supported by CSR funding from IndusInd Bank.